Supply chain management, a crucial aspect of modern business operations, involves optimizing processes to enhance efficiency and minimize costs. Let’s dive into the intricate world of managing supply chains with a fresh perspective and a touch of American high school hip style.

From defining supply chain components to discussing risk management strategies, this overview will explore the essential elements of supply chain management in a captivating manner.

Overview of Supply Chain Management

Supply chain management is a crucial aspect of business operations that involves the planning, coordination, and control of the flow of goods, services, and information from the point of origin to the point of consumption. It plays a vital role in ensuring that products are delivered to customers in a timely, efficient, and cost-effective manner.

Key Components of a Typical Supply Chain:

Key Components

- Suppliers: The companies or individuals that provide raw materials or components needed for production.

- Manufacturers: The entities responsible for converting raw materials into finished products.

- Distributors: The intermediaries that help in transporting and storing products before they reach the end consumers.

- Retailers: The businesses that sell products directly to consumers.

Role of Supply Chain Management in Enhancing Efficiency and Reducing Costs:

Importance of SCM

Supply chain management plays a critical role in enhancing efficiency by optimizing processes, reducing lead times, and minimizing waste. By streamlining operations and improving coordination between different stakeholders, businesses can achieve cost savings, increase customer satisfaction, and gain a competitive edge in the market.

Supply Chain Planning

Supply chain planning is like mapping out a game plan to make sure all the pieces of the supply chain puzzle fit together smoothly. It involves figuring out how to efficiently move products from suppliers to customers while keeping costs low and customer satisfaction high.

Different Strategies in Supply Chain Planning

- Just-in-Time (JIT) Inventory: This strategy focuses on having products delivered exactly when they are needed, reducing excess inventory and storage costs.

- Vendor-Managed Inventory (VMI): In VMI, the supplier manages the inventory levels at the customer’s location, ensuring that products are always available without overstocking.

- Cross-Docking: This strategy involves unloading incoming shipments from suppliers and loading them directly onto outgoing vehicles, reducing storage time and costs.

Impact of Demand Forecasting on Supply Chain Planning

Demand forecasting is like predicting the future – it helps supply chain planners anticipate how much of a product will be needed and when. This information is crucial for making decisions on production levels, inventory management, and transportation logistics. When demand forecasting is accurate, it can help prevent stockouts, reduce excess inventory, and improve overall supply chain efficiency.

Logistics and Inventory Management

Logistics and inventory management play a crucial role in the success of a supply chain. Let’s dive into the details of these key components.

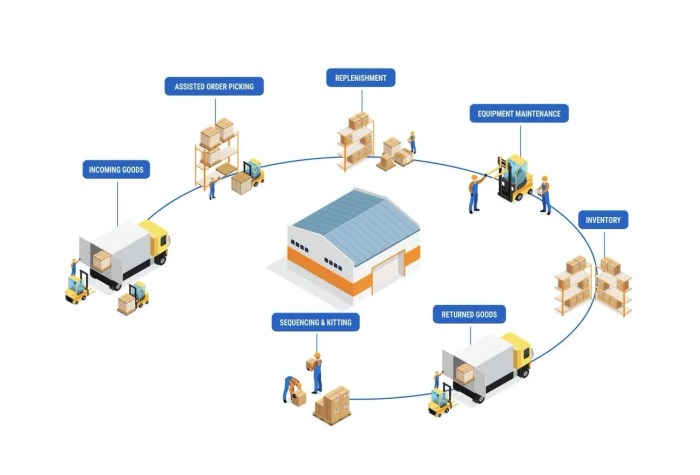

Logistics in Supply Chain Management

Logistics in the context of supply chain management refers to the process of planning, implementing, and controlling the efficient flow of goods, services, and information from the point of origin to the point of consumption. It involves the coordination of various activities such as transportation, warehousing, packaging, and distribution to ensure the smooth operation of the supply chain.

Importance of Efficient Inventory Management

Efficient inventory management is essential for optimizing the performance of a supply chain. It helps in ensuring that the right amount of inventory is maintained at the right place and time to meet customer demand while minimizing holding costs. By effectively managing inventory levels, companies can reduce stockouts, improve order fulfillment rates, and increase overall efficiency in the supply chain.

Technologies and Tools for Optimizing Logistics and Inventory Management

To enhance logistics and inventory management, companies utilize various technologies and tools such as:

- Warehouse Management Systems (WMS): WMS software helps in tracking inventory levels, managing warehouse operations, and optimizing storage space.

- Transportation Management Systems (TMS): TMS solutions assist in route planning, carrier selection, and freight auditing to streamline transportation processes.

- Inventory Optimization Software: These tools use data analytics to forecast demand, optimize inventory levels, and reduce excess stock.

- RFID Technology: RFID tags enable real-time tracking of inventory, improving visibility and accuracy in the supply chain.

- Supply Chain Analytics: Advanced analytics tools provide insights into supply chain performance, helping companies make data-driven decisions for continuous improvement.

By leveraging these technologies and tools, organizations can achieve greater efficiency, cost savings, and customer satisfaction in their logistics and inventory management processes.

Supplier Relationship Management

In the realm of supply chain management, fostering strong relationships with suppliers is crucial for the success of any business. These relationships are built on trust, communication, and collaboration, which ultimately lead to improved efficiency, quality, and cost-effectiveness in the supply chain.

Significance of Supplier Relationship Management

Effective supplier relationship management can result in a wide range of benefits for a company. By establishing strong partnerships with suppliers, businesses can ensure a stable and reliable supply of goods and services, reduce lead times, and enhance overall operational performance. Moreover, strong relationships with suppliers can lead to innovations, cost savings, and competitive advantages in the market.

- Improved quality control: By working closely with suppliers, businesses can monitor and maintain the quality of materials and products, ensuring consistency and reliability.

- Cost savings: Strong relationships with suppliers can lead to better pricing agreements, discounts, and reduced operational costs, ultimately improving the company’s bottom line.

- Risk mitigation: Collaborating with suppliers can help businesses identify and address potential risks in the supply chain, such as disruptions, delays, or quality issues, allowing for proactive solutions and contingency plans.

Strategies for Effective Supplier Relationship Management

To enhance supplier relationships, businesses can employ various strategies to strengthen communication, trust, and collaboration.

- Open communication: Establishing clear lines of communication with suppliers is essential for sharing information, addressing concerns, and resolving issues in a timely manner.

- Transparency: Being transparent about business goals, expectations, and performance metrics can help build trust and mutual understanding between the company and its suppliers.

- Collaboration: Engaging in joint planning, problem-solving, and decision-making with suppliers can foster innovation, process improvements, and mutual benefits for both parties.

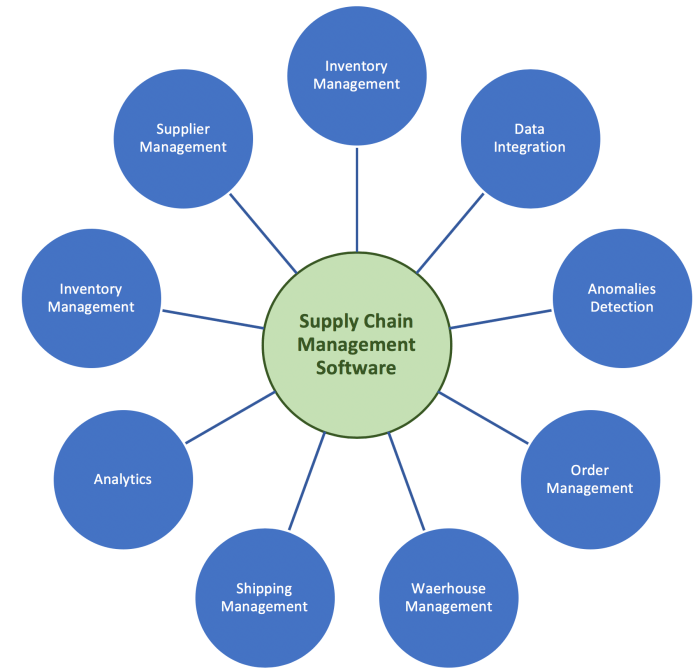

Technology in Supplier Relationship Management

Technology plays a crucial role in streamlining communication and collaboration with suppliers, making it easier to exchange information, track performance, and manage relationships effectively.

Utilizing supply chain management software, electronic data interchange (EDI), and supplier portals can facilitate real-time communication, order processing, and data sharing between businesses and their suppliers.

By leveraging technology tools and platforms, businesses can enhance visibility, transparency, and efficiency in their supplier relationships, leading to improved supply chain performance and competitive advantage in the market.

Risk Management in the Supply Chain: Supply Chain Management

In supply chain management, it is crucial to address and mitigate various risks that can disrupt the flow of goods and services. By identifying common risks and implementing effective strategies, businesses can ensure smooth operations and maintain customer satisfaction.

Common Risks in Supply Chain Management

- Supplier Reliability: Dependence on a single supplier can lead to delays or disruptions if they face issues like bankruptcy or production problems.

- Natural Disasters: Events like earthquakes, hurricanes, or floods can impact transportation routes, warehouses, and production facilities.

- Demand Volatility: Sudden changes in customer demand can lead to overstocking or stockouts, affecting profitability.

- Cybersecurity Threats: With the increase in digitalization, cyber attacks on supply chain systems can result in data breaches or system failures.

Strategies for Mitigating Supply Chain Risks

- Diversifying Suppliers: Working with multiple suppliers can help spread the risk and ensure a steady supply of goods.

- Creating Contingency Plans: Developing backup plans for different scenarios can help minimize the impact of disruptions.

- Utilizing Technology: Implementing supply chain management software and tracking systems can improve visibility and responsiveness.

- Collaborating with Partners: Building strong relationships with partners and stakeholders can facilitate communication and problem-solving during crises.

Importance of Having a Robust Risk Management Plan

A robust risk management plan is essential for businesses to proactively identify, assess, and mitigate potential risks in their supply chain. By having a structured plan in place, companies can minimize the impact of disruptions, maintain operational efficiency, and ensure customer satisfaction.